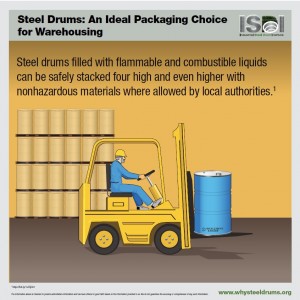

Warehouse and shop floor space is premium real-estate in the supply chain. The need to properly store readily accessible materials for use in a production process or for shipment to a customer creates a daily challenge, one in which planning and efficiency can be important allies. To maximize available space effectively, the ability to vertically store (stack) packaging is essential.

Steel drums are widely used in the supply chain to ship a range of products, both dry bulk and liquid. The hallmarks of steel are its consistent strength and durability—qualities that contribute to the predictability of steel drums for packaging hazardous and non-hazardous materials. Steel drums’ standardized design and resistance to extreme temperatures and humidity enhance the safety and security of hazardous and non-hazardous materials. These same characteristics contribute to their excellent stacking strength in circumstances where space is at a premium.

To afford proper protection for such packagings, it is important to keep in mind the characteristics of the materials contained in the drums. They should be properly stacked and unitized based on these characteristics for transportation and subsequent storage in a workplace or warehouse. Packaging industry testing and real-world experience has demonstrated that steel drums containing hazardous materials with a specific gravity of 1.5 or less can be safely stacked four-high.

In addition, proper handling, palletization and related recommendations should be followed. In compliance with Federal regulations (49 CFR §178.606), steel drums are subject to a test where a top load force equivalent to a 3-meter high stack (9.842 feet), with the specific gravity of the intended lading, is applied is at ambient temperature for 24 hours. If a drum passes, it is safe for use under the tested conditions and contents.

The Industrial Steel Drum Institute (ISDI) has published more detailed information on stacking steel drums at https://whysteeldrums.org//alerts/. Alert 15-03 lays out recommended best practices companies should follow when considering storing their materials in stacked drums. Other important considerations are addressed in earlier ISDI Alerts, such as steel drum accessory compatibility (Alert 14-06), choosing steel drum linings (Alert 14-07), and a buyer’s and shipper’s guide for choosing the proper packaging for both regulated and non-regulated materials (Alert 14-08). Taken together these four Alerts provide vital information that will assist steel drum users in choosing the proper packaging for the materials being shipped.

Click Here to Download Issue 5