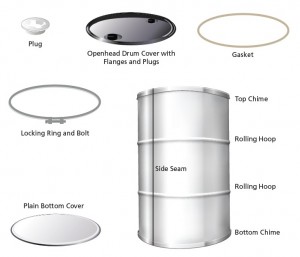

There are numerous factors one must consider when specifying the elements of a new steel drum for transporting hazardous and non-hazardous materials. One important factor relates to the need for a customer to carefully consider all materials of construction, especially those that may come in contact with the fill product in the container. It is vital that plugs, flanges, gaskets, interior treatments, removable liners and end-seam sealers be given the same scrutiny as interior linings to ensure that these components will perform satisfactorily.

The importance of such scrutiny is underscored by the requirement in Section 173.24(e)(1) of Title 49 of the Code of Federal Regulations, which stipulates that it is “the responsibility of the person offering a hazardous material for transportation to ensure that such packagings are compatible with their lading.” While the packaging manufacturer stands ready to work with the customer in providing a steel drum that meets all the requirements of the product being shipped, the provision cited above underscores the essential role that the drum buyer plays in ensuring the safety and integrity of its product during transport.

Compatibility in this instance has two considerations. One relates to the effect of a product on packaging components and the other to the effects of the packaging components on the contained product. While many of a steel drum’s components have been laboratory and field-tested over the years to ensure they are suitable for the lading being packaged, innovations in container technology as well as new fill products and reformulations of longstanding ones could result in previously acceptable container components no longer performing as expected.

Consequently, it is prudent periodically to evaluate all container components to be sure they meet the specific performance requirements for the products packaged for transport. The various component suppliers are a prime source of information; they are always available to provide valuable suggestions relating to the materials they provide. In most cases, a simple lab test can prove invaluable.

Whether conducting your own laboratory tests, enlisting the expertise of the various components suppliers, or consulting with a third-party laboratory or steel drum manufacturer, it is prudent to bear in mind the adage “an ounce of prevention is worth a pound of cure” when it comes to container component selection. Full disclosure of the characteristics of the product to be packaged for shipping is essential to determine the correct drum components, including gaskets, plugs, seaming compound, fittings, linings and removable liners, etc., for a particular application.